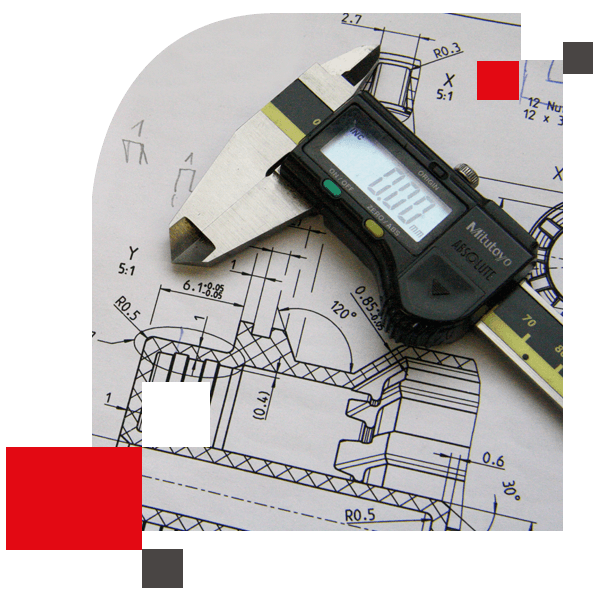

We are providing service for 2D & 3D measurement. We can scan job from small to big size. Also can compare & check deviation in dimensions with old drawing. Scanning accuracy is ±25 micron.

About our Company

About our Company

The company’s success can be at tributes to its constant dedication to good quality standards and reliability. Our customers, who implemented projects with Phitech Solutions can be assured to have specialists that stay in constant cont act with their project in order to bring ideas to life, turn them into process, implement them with st ate of art manufacturing technology and specifically adopt the product to the end customer.

Established in 2018, Phitech Solutions is one of the leading manufacturer of plastic moulds.

With over 6 years of experience and real focus on customer satisfaction, you can rely us for your next development of product and project. We provide a professional service for individual and corporate customers.

We are manufacturing MOULD for processes as below.

Concept/Idea – Design – Prototype – Analysis – Manufacturing – Validation – Reality

We are providing service for 2D & 3D measurement. We can scan job from small to big size. Also can compare & check deviation in dimensions with old drawing. Scanning accuracy is ±25 micron.

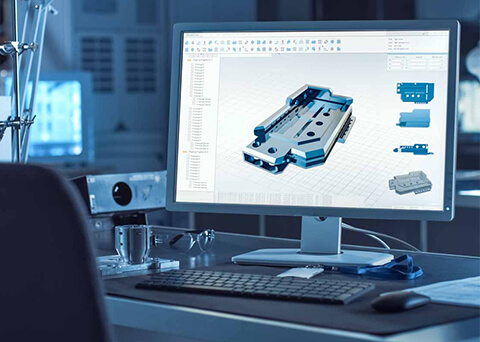

Our design department is having facility of CAE for injection moulding, provide depth analysis for complete moulding process on the world best CAE simulator “MOLDEX 3D”.

We work closely with our engineering staff from the initial design concept to the detailed mould design to enhance robustness, manufacturability, & maintainability of mould.

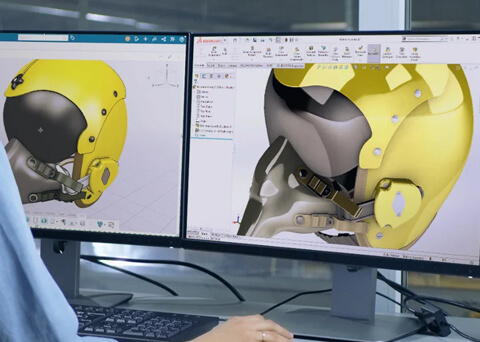

We know our customers, and we design for them. Understanding the parts you need, we design for market acceptability. We promote creativity in product design allowing customer to create shapes & sizes.

Clients we are working with